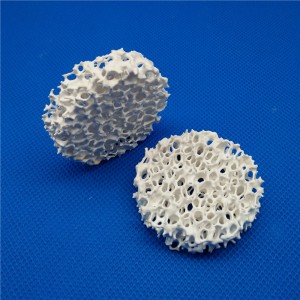

Sefa ya Alumina Ceramic Foam ya Sefa ya Aluminiyamu Yosungunuka

Sefa ya Alumina Ceramic Foam ya Sefa ya Aluminiyamu Yosungunuka

| kukula (mm) | Dimension (inchi) | Kuthira (kg/s) | Sefa mphamvu (tani) |

| 178*178*50 | 7*7*2 | 0.2-0.6 | 5 |

| 228*228*50 | 9*9*2 | 0.3-1.0 | 10 |

| 305*305*50 | 12*12*2 | 0.8-2.5 | 15 |

| 381*381*50 | 15*15*2 | 2.2-4.5 | 25 |

| 430*430*50 | 17*17*2 | 3.0-5.5 | 35 |

| 508*508*50 | 20*20*2 | 4.0-6.5 | 45 |

| 585*585*50 | 23*23*2 | 5.0-8.6 | 60 |

| Zakuthupi | Alumina |

| Mtundu | Choyera |

| Pore Density | 8-60 ppi |

| Porosity | 80-90% |

| Refractoriness | ≤1200ºC |

| Kupindika Mphamvu | > 0.6Mpa |

| Compression Mphamvu | > 0.8Mpa |

| Kulemera kwa voliyumu | 0.3-0.45g/cm3 |

| Thermal shock resistance | 6 nthawi / 1100ºC |

| Kugwiritsa ntchito | Aluminiyamu, Aluminiyamu aloyi ndi zina Non-ferrous aloyi |

1. Chotsani madzi achitsulo osungunuka

2. Dongosolo losavuta lolowera

3. Kupititsa patsogolo zitsulo zazitsulo za castings

4. Chepetsani kusamvana kwa ma castings

5. Kupititsa patsogolo kuponya khalidwe mlingo

6. Kuchepetsa kuponyera mkati re-oxidation zolakwika

7. Chepetsani zolakwika zapamtunda pambuyo pokonza ma castings

1.Kuchulukitsa kwamadzimadzi

Kuchotsa ma inclusions kumapangitsa chitsulo kukhala chamadzimadzi, zomwe zimapangitsa kudzaza kwa nkhungu kosavuta, kapangidwe kabwino kaponyedwe kabwinoko, komanso kutulutsa gawo lopyapyala bwino.

2.Reduced Mold ndi Die Wear

Kuchotsedwa kwa inclusions ndi zinyalala zina zopanda zitsulo kuchokera kusungunuka kumachepetsa kufa kwa soldering ndi nkhungu-zitsulo, zomwe zimawononga nkhungu pamwamba ndi moyo wautumiki.

3.Utali Wachida Moyo

Oxide komanso ma intermetallic inclusions amapanga "malo olimba" omwe amawononga zida pamakina ndi kumaliza ntchito.Kusefera kumachepetsa kuvala kwa zida ndikuwonjezera zokolola.

4.Ochepa Amakana

Inclusions nucleate porosity, imapanga misozi yotentha panthawi yolimba, imayambitsa zowonongeka zomwe zimawononga maonekedwe, ndipo nthawi zambiri zimachepetsa makina.Nthawi zambiri, zosefera zimakana kuchoka pazifukwa zotere mpaka ziro.Kupititsa patsogolo zokolola kufika pafupi ndi 100% ndi kuchepetsa kukana kufupi ndi 0% ndizofala.

1. Kuponya mchenga

2. Kuponya zipolopolo

3. Low-pressure kufa kuponyera

4. Kuponyedwa kokhazikika kwa nkhungu

5. Kugwira ndi kusamutsa machitidwe